Industrial design

Strategic design

We analyze all variables of a project to define a strategy that aligns with the current and future landscape

Strategic design must define the objectives and scope of the project. To do this, it is necessary to understand our clients, their needs, and expectations, and to devise a strategy that allows us to achieve a product adapted to the competitive global market.

We analyze the project considering a multitude of factors and take into account all the requirements that our product must meet to satisfy these needs and objectives.

In this phase, we carry out an extensive analysis in which we consider the following factors that help us define a strategy aligned with the product:

- Document with the most relevant information, conclusions drawn together with the client, and execution strategy.

- Document with the statement of needs and product specification definitions (EDP).

Formal design

We shape solutions that meet all the project requirements

Once the requirements to be met are defined, solutions are provided from a global perspective, seeking maximum functionality in coherence with important aspects such as aesthetics, ergonomics, user experience, or manufacturing parameters, all while seeking to maximize the value proposition.

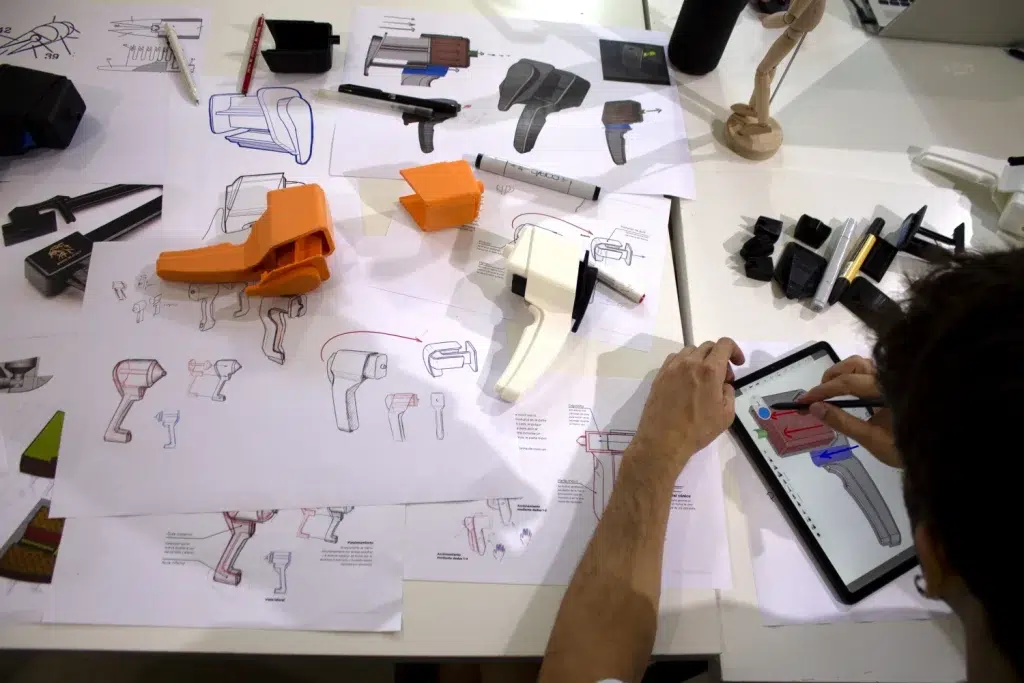

In this phase, sketches and 3D designs are generated to evaluate the different available options. After selecting the most suitable option, a basic floor plan is created to study the different manufacturing options and obtain an estimated cost.

As support for decision-making, basic prototypes are made for the study of parameters involving simplified volumetrics and operation.

- Presentation of a formal proposal with the conceptual approach and brand image.

- Document with a mood board of aesthetic and functional references.

- Initial design proposals through sketches.

- Photorealistic 3D renders of selected options.

- Link for 3D visualization and navigation.

Product development and engineering

We develop all technical aspects of the product

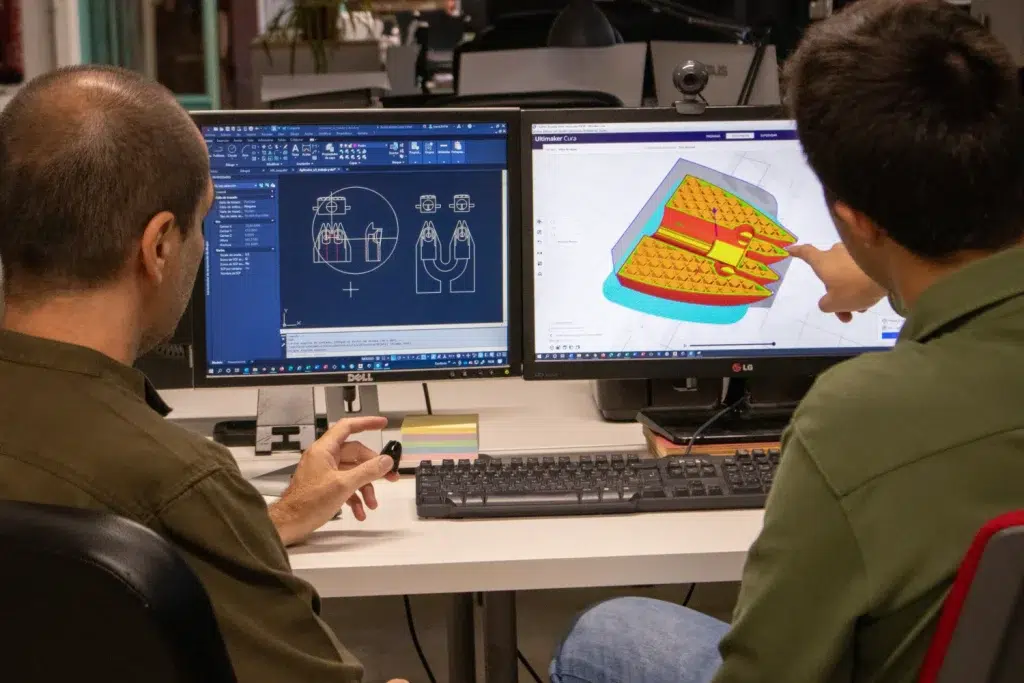

After formally and functionally defining the appropriate design option, we proceed with its development, generating all floor plans and necessary files for the final verification of compliance with all requirements.

In this phase, it is important to maintain constant contact with manufacturers and suppliers for proper control of compliance with all quality standards within the production chain. It is also in this phase where a fully functional prototype is developed and manufactured, verifying and modifying all necessary parameters for its correct operation.

- Floor plans and necessary files (CAD-CAM) for prototype manufacturing. Transparent budgeting and quotation submissions from manufacturers and suppliers for prototype production.

- Presentation of the constraints of each supplier and manufacturer with guidance in the decision-making process.

- Documentation of prototype analysis and, if necessary, action lines for making the relevant modifications for the final product’s production readiness. Link for 3D visualization and navigation.

Production

We manage the manufacturing and supplier tracking to obtain the desired product

In this phase, the manufacturing of the first units is initiated, which must be thoroughly reviewed to ensure that all parameters involved in the manufacturing process meet the established requirements.

It’s important to manage and coordinate all manufacturers and suppliers involved in the project, ensuring that all quality standards are met both individually for each piece and for the product as a whole.

- Reports with final modifications and changes for the start of production.

- Transparent budgeting and quotation submissions from selected manufacturers and suppliers for production.

- Sending all floor plans, files, and necessary documentation for the correct manufacturing of the product.

- Sending production management reports.

- Technical test report (ITP) for product manufacturing validation.

- Project closure documentation with the compilation of all information generated throughout all phases involved in the development and manufacturing of the product.

Completed projects

AYCO

A terminal for ticket printing and reading.

AYCO is a terminal designed for Global Salcai-Utinsa, for ticket printing and transport pass reading through barcode or magnetic scanning.

The design focused on integrating multiple electronic components safely and accessibly. Design for Manufacturing was prioritized by using assemblies to reduce costs, and the design was validated through prototyping.

Lebit

A contactless terminal for transport passes.

Lebit is a compact and ergonomic terminal designed for Global Salcai-Utinsa, for "contactless" transport pass reading, with a screen that displays relevant information to the user.

The design was adapted to fit the vertical bars near bus doors, incorporating an anti-vandalism system. Design for Manufacturing was prioritized using injected plastic assemblies, and the design was validated through prototyping.

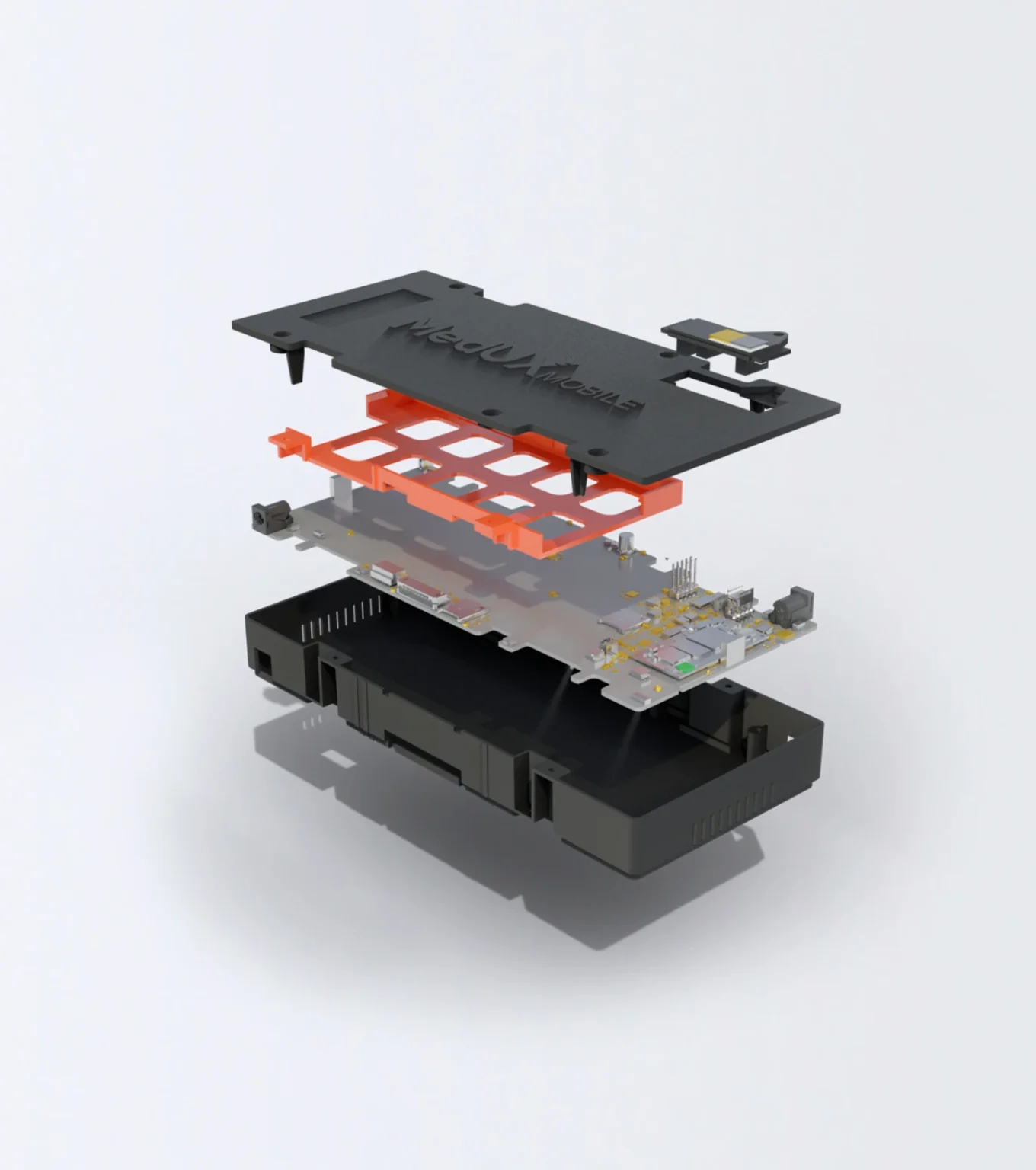

MedUX

A redesign of the housing for the MedUX Mobile 3.0 probe.

The project focused on adapting the previous model to new requirements. A mechanical study was conducted to integrate components, and designs were made for external connections, board distribution, and an optimized intermediate housing to ensure stability and correct assembly.

The modifications were prototyped using 3D printing, and the final files were prepared for mass production in China.

Vector Screen

A support for sliding guides for interactive displays.

The new version of the Vectorscreen system is a lightweight and precise pattern recognition system with a free axial movement arm that uses software to launch applications upon detecting images, redefining interactive experiences in museums.

It was designed using components and with an adaptable support for interactive material. It was developed through prototyping to ensure its functionality before mass production.

Success Stories

Advantech has collaborated with Trem in developing solutions for various industries, including transport, medical, and others. The Trem team has added value with high-quality designs based on efficiency and usability.

Working with Trem is very easy and stimulating. They have vision and perfectly blend technical and aesthetic aspects. They make you feel part of the process while fully embracing the project with their involvement and professionalism. They do not rest until the expected result is achieved. Highly recommended.

They understood the project and materialized our needs.

Working with TREM is very rewarding. From the first project, they have always been involved in the development of our client solutions. No matter how complex it may be, we know we can count on them, their knowledge, and their experience. It's a real pleasure.